Powercuts in our part of the world are pretty uncommon these days, thank goodness. But, on the rare occasion they do happen, you become acutely aware of just how much we've come to rely on electricity. Well, the same goes for our hen houses - it powers the lights, the nest boxes, the feeder motors, the timers, the sensors which regulate the feeders, the water lines, the master electronic control unit which regulates the whole thing - it's pretty essential to the smooth running of the farm. This week, we're putting our electrician's hats on...

For the twenty or so years we've been an organic egg farm, all of our hen houses have been run on 12V power. Back then it was far more energy efficient than 240V and, therefore, more environmentally sustainable as everything from the light bulbs to the motors drew a lot less power. Today the technology has advanced far enough that the power draw is now virtually the same, and there are some significant advantages to converting our sheds over to 240V. So that's what we're in the process of doing.

One advantage is that it's getting increasingly difficult to get the parts needed to maintain the old system. Things like motors are simple enough, as they're not much different to the motor that your windscreen wipers use. But others, like the feed sensors and electronic control units, are not 'off the shelf' parts and they're getting increasingly difficult to find. On top of that, while we're pretty good at servicing and dealing with any small to medium problems ourselves, anything more serious needs a specialist and they too can be hard to come by (especially at the times of day we're likely to need them).

So far about 50% of our sheds have been converted and, before the next flock comes in, we're in the process of upgrading this one. So today it's feeder motors and nest boxes...

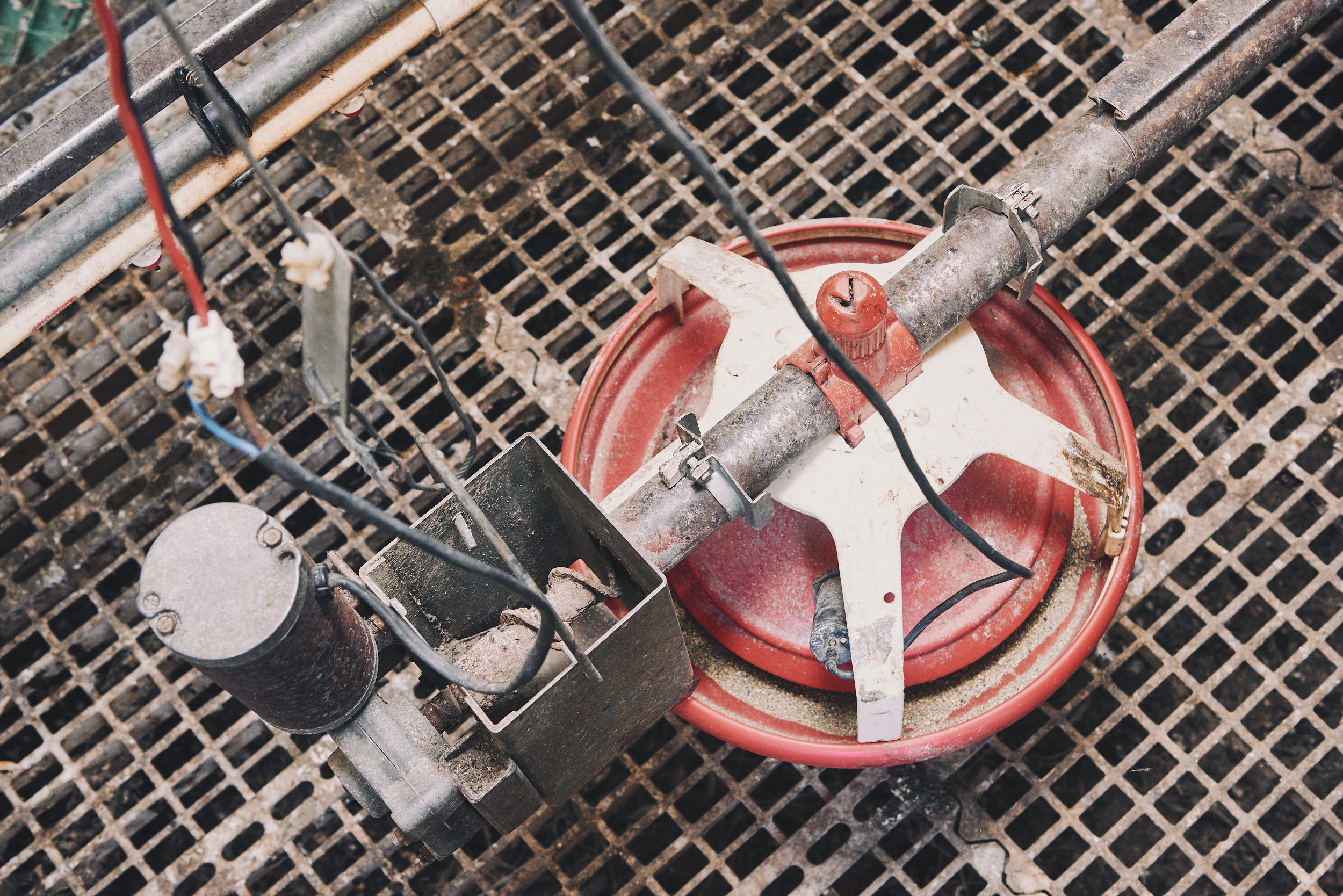

On each side of the chicken shed is a line of feeders with a motor on the end. A timer starts the motor 5-6 times a day and feed is drawn from the hopper outside by a 'flex auger' filling each feeder down the line. Then a touch sensor at the end of the line stops the motor when all the feeders are full.

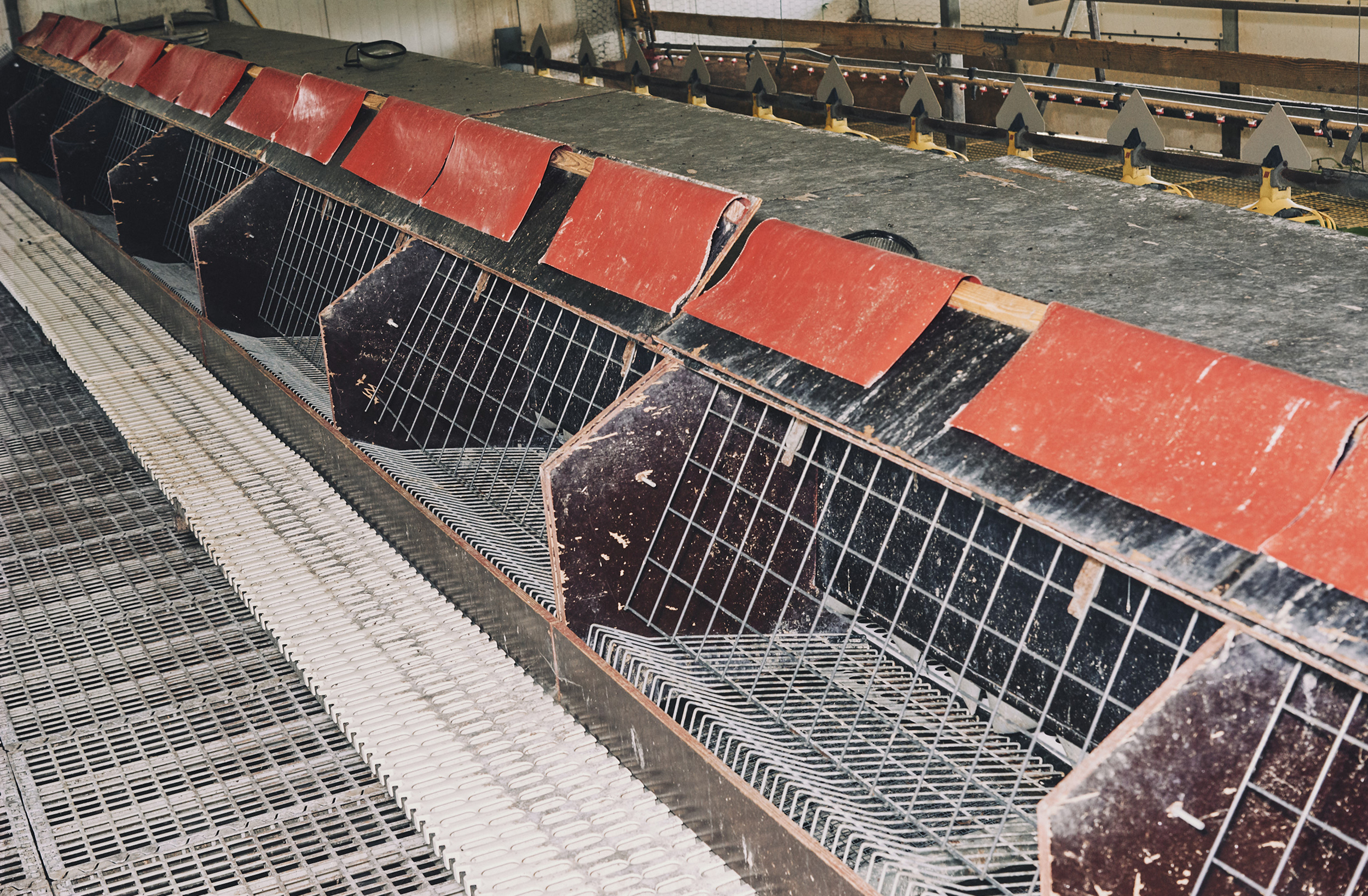

With the nest boxes, a central motor opens them at sunrise and then slowly closes them at around 5pm to make sure the birds don't go to bed in the there. Not only does it stop them from fouling the 'laying mats' which go on the floor of every box, but it also stops them from getting broody if they were to stay in there over night.

This kind of work can only be done when the hen houses are empty obviously. So it's not something we can do all in one go or even simply between flocks. Because we use mobile hen houses, as we believe it's better for the land and therefore the birds, there's a lot of other work that needs to be done to prepare each house before every new flock.

As with so much of what we do it is, by necessity, an on-going process. But, when timing permits, each shed is getting converted and the parts from previously converted sheds we can use to service the other hen houses until they too can be converted.