Ageing is something we all have to contend with at some point or another. Despite our best efforts, it's inescapable - doesn't matter whether your human, fish or fowl. Much like us, the older a chicken gets the less productive it becomes. After a year and half or so they start to lay fewer eggs and the shell quality starts to deteriorate meaning, ultimately they can no longer be graded, boxed and sold.

We're an organic egg farm for a reason: the welfare of both our birds and our land is incredibly important to us and something we take great pride in. It's a holistic approach that has worked for us for more than twenty years - we take care of them, and they take care of us. And that sentiment doesn't stop just because they're not able to produce the kind of eggs our customers expect from us. So when it comes to their retirement, whenever possible, we work with Fresh Start For Hens who specialise in finding them new homes.

Fresh Start is a not-for-profit organisation with around 200 volunteers nationwide. Whether it's a town, city or country garden; an allotment, school or residential care home, F.S.F.H exist to provide new homes for hens and advice or information to potential new owners. Like us, they are committed to the welfare of the birds and, for that reason, they won't re-home to anyone wishing to sell them on or for further commercial purposes.

The work starts before they arrive - we let them know how many birds we have to be collected (2,100 on this occasion) and they go about allocating the hens to new homes and enlisting volunteers to help with collection.

On collection day, the team arrives at 5am for an early start when the chickens are slightly more docile. You've heard the expression "it's like herding cats", well this is not dissimilar. It's a well-practiced system at this point which sees one team moving the birds in groups to the scratch area where another team collects them and transfers them to specially designed poultry crates. Another member of the team monitors each crate to ensure that their legs and wings are comfortable and that they're not overcrowded before being moved outside.

The poultry crates provide a safe environment for transportation. They wouldn't want to live in one but, for the relatively short amount of time it takes to transport them to their destination it is by far the best solution and causes minimal stress to the bird.

Once they are settled and happy in their temporary accomodation, the team then move them outside so they can be 'counted out' and assigned to one of the waiting vehicle's that have been hired for the job. When a vehicle has it's designated number of birds it heads off to one of 33 collection points around the country, where the birds are let out and await collection by their new families.

After about 4 hours of hot and dusty work, the Fresh Start team have rounded up all the birds and get ready for the next phase of their journey. They have collection points from Cumbria to Wales and the West Country and rely on volunteers to carry out the work they do re-homing chickens from farms nationwide. You can register your interest in re-homing by going to fsfh.org.uk or find out more about what they do and how you can help on facebook.

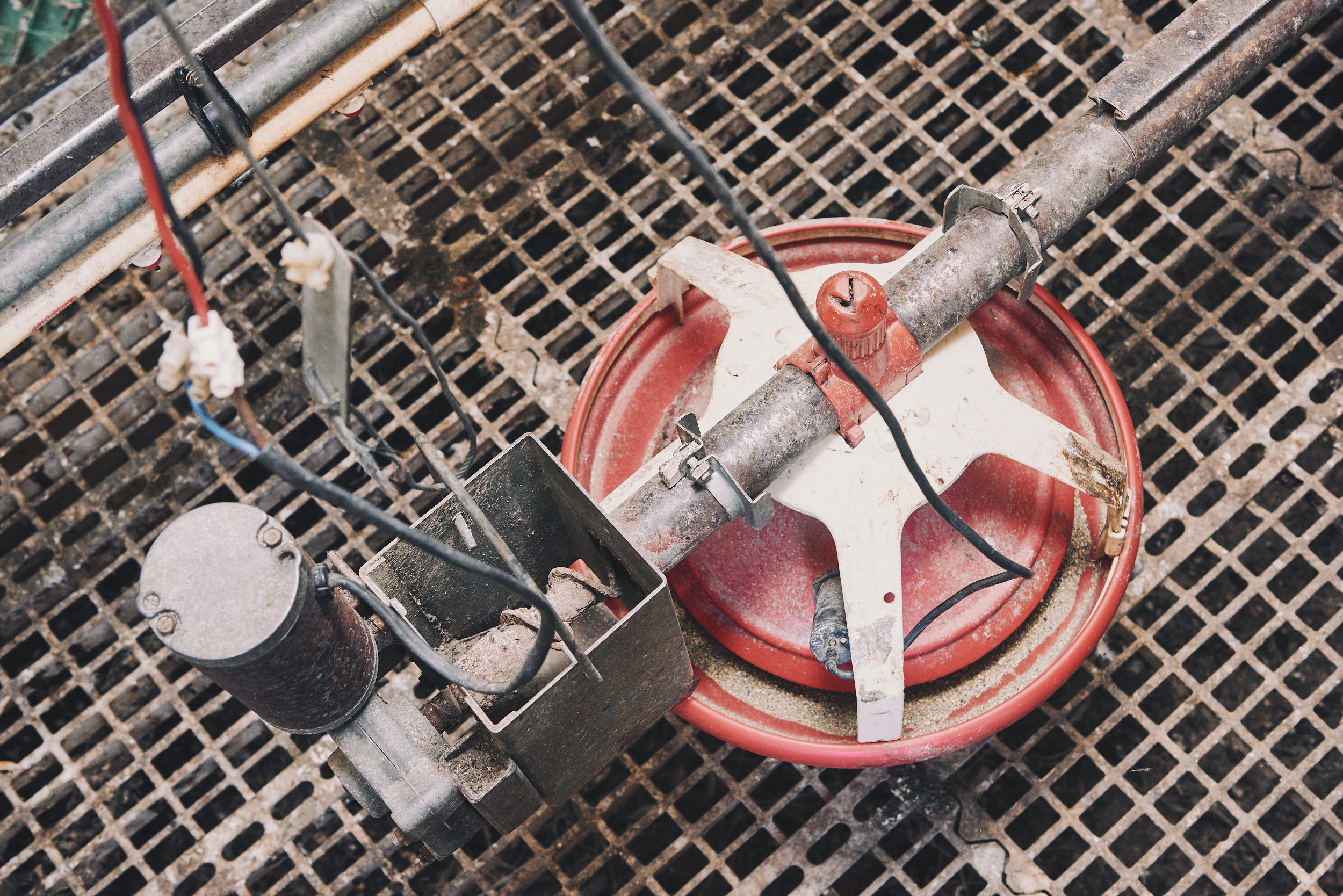

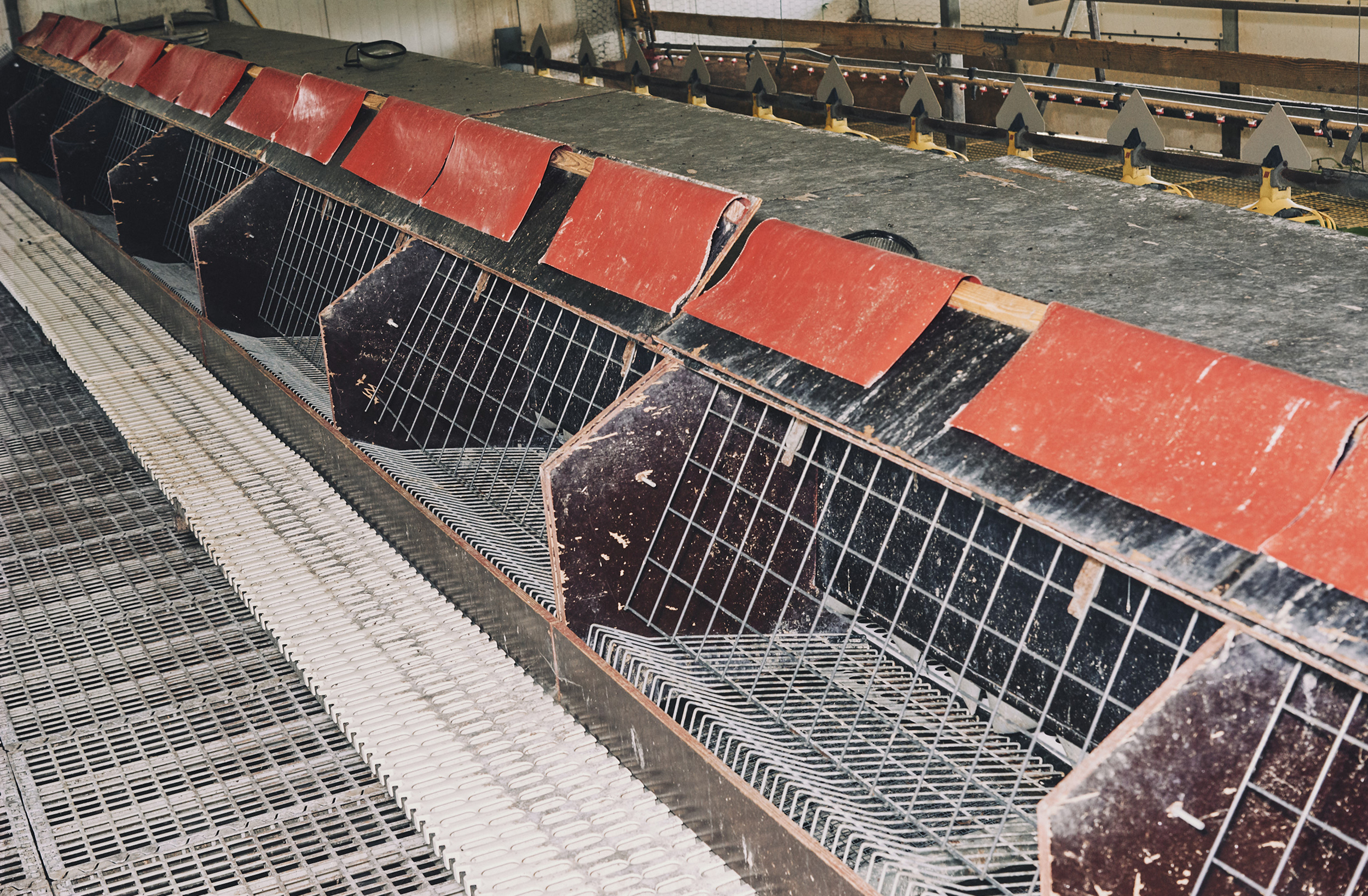

For us, we've now got just a few weeks to get everything ready to welcome a new flock of birds...